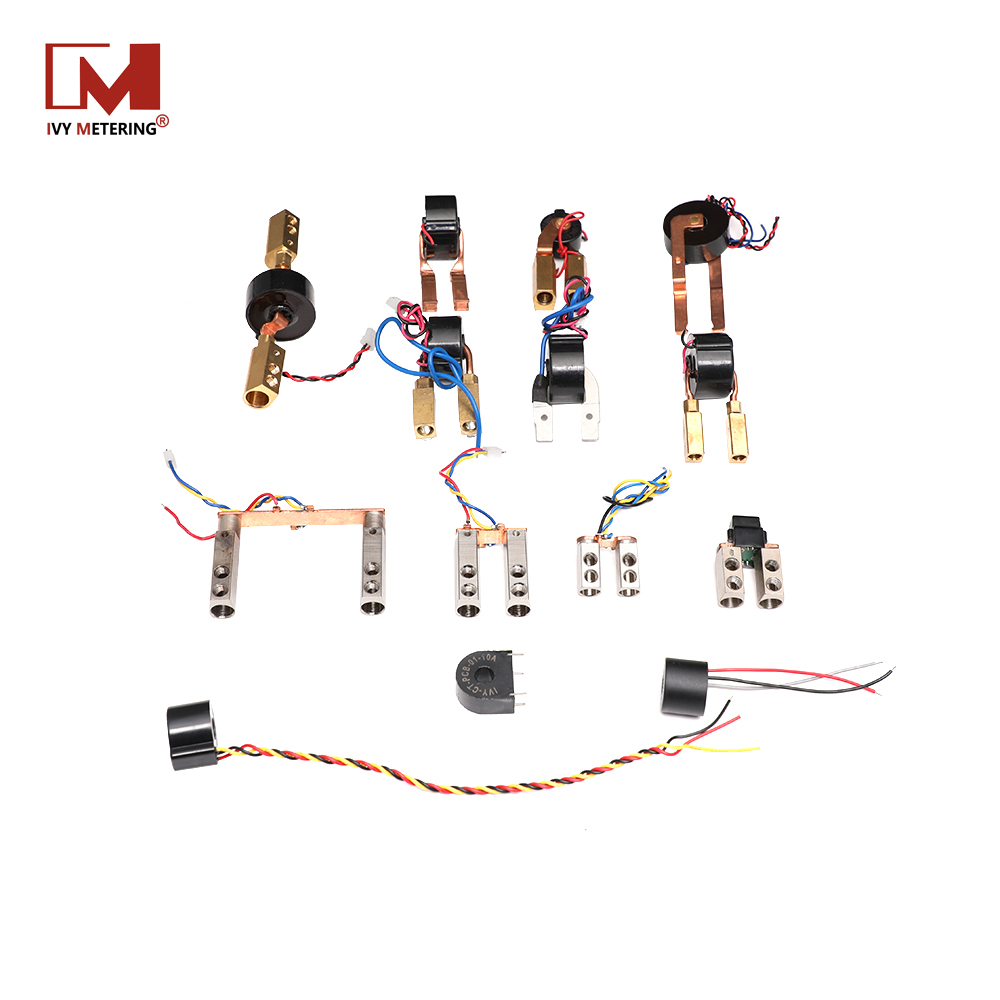

Process Flow of Transformer

As one kind of popular product in measuring field, what are they producing process? Let study it together today.

Packing: after passing the inspection, the special iron core of the transformer is wrapped up with the special insulation material of the transformer. Waste insulation materials are produced in this process.

Secondary Coil Winding: according to the parameters provided by the operation process sheet in the workshop, the secondary coil of the transformer is wound by the special equipment manufactured by the transformer.

Secondary coil test: the wound secondary coil of the transformer must be inspected by the special testing equipment of the transformer. After meeting the national standard, it will flow into the next process.

Primary coil winding: the qualified secondary coil of the transformer is wrapped according to the technical operation order, and the primary coil of the transformer is made into semi-finished products by wrapping in the winding workshop. After passing the retest of the special instrument transformer, it flows into the next process.

Mold installation: After the qualified semi-finished transformer is sent to the next process, the mould of the transformer shall be selected according to the model and specification on the semi-finished product process card. The semi-finished products shall be loaded into the mould according to the technological requirements of the semi-finished products.

Vacuum pouring: load transformer semi-finished products within the mold heating drying after reaching the technological requirements, into the transformer special epoxy vacuum casting equipment, will be configured epoxy composite material with the method of vacuum pouring into a mold, vacuum degassing treatment, after reaching the technological requirements of vacuum degree, surprises to take out the mould into the electric heating oven heating curing

Mold release: the epoxy mixture (epoxy resin and silicon powder) in the electric heating oven is cured by heating in the mold. After the mold is taken out of the oven, the mold is opened and the transformer is taken out.

Remove foreign body: after the de-burring of the transformer after demodulation meets the production requirements, it is sent to the next process. In this process, epoxy mixture is generated

Test: Before the transformer leaves the factory, the routine test of each transformer must be carried out with special equipment for it. If it meets the national standards, it shall be approved to leave the factory by the experimenter affixes official seal.

All of above is the produce process, if you want to know more about details and have more free technical points, plz click

www.ivy-metering.com

Previous: Water Pump Dedicated Relay IM901

Previous: Water Pump Dedicated Relay IM901