Why do we need EV charger protection and safety components?

As the new energy vehicle industry continues to develop, more and more residential communities and commercial buildings are building or renovating electric vehicle charging piles. As a public facility, the design of charging piles is related to life safety. Preventing leakage that may occur during charging is a necessary measure for every electric vehicle and charging pile manufacturer.

So, what type of RCD should be chosen for adequate protection?

According to the IEC 61851 standard, any charging station must be protected against 6mA smooth DC and 30mA AC fault current.

The AC type RCD is not suited for electrical devices since it induces a pulsating direct current (DC) that is not detectable by this form of RCD and is even outlawed in some countries.

The A type works for most electronic devices, but specific devices might create a smooth DC current in the network, which can blind the type A RCD.

In such a case, the type A RCD would not trigger even when a fault has occurred. Faulty charging stations can sometimes cause higher DC currents, making this type useless.

The B type RCD is the go-to solution for safety when installing EV chargers, but it is also the most expensive.

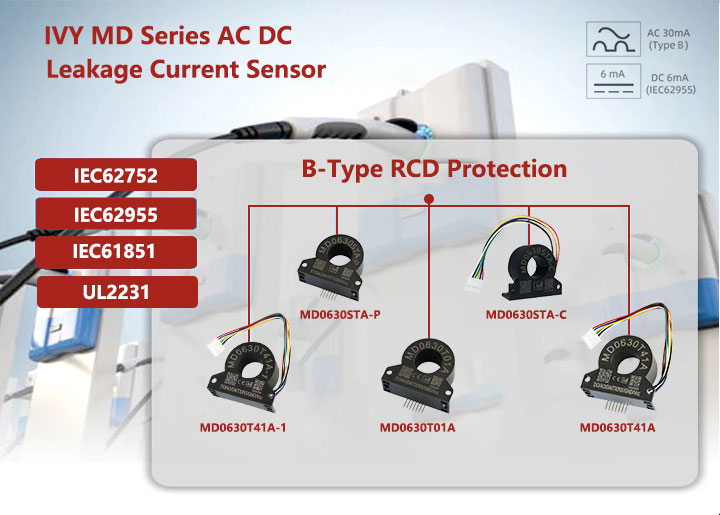

IVY Metering has been deeply involved in the charging pile industry for many years, and its products have a certain reputation and influence. Based on the current situation that the residual current technology of domestic charging piles is relatively backward, overseas products are expensive, and the delivery time is long, IVY Metering has independently developed the core circuit through in-depth market research and long-term technical accumulation, and launched a safe and reliable charging pile residual current protection module-MD0630T01A/MD0630STA-C/P series.

Product advantages

It can be widely used in the electric vehicle charger (charging pile) industry, using fluxgate detection technology to detect DC, AC and various pulsating residual currents, meeting the residual current detection standards of IEC62752 (mode 2) and IEC62955 (mode 3), and can detect B-type residual current waveforms, and can detect 6mA DC residual current, trigger sensitively, and respond to leakage events in a timely manner.

B-type detection, safe and reliable

The product detects B-type + 6mA leakage, which has a wider detection range, safer and more reliable than the A-type + 6mA on the market.

As the most comprehensive residual current detection method, B-type residual current detection has specified corresponding application requirements in the automotive electronics, charging pile and other industries. In the electric vehicle charging system, rectifier, PFC and other circuits often have high-frequency sinusoidal AC residual current, pulsating DC residual current, and smooth DC residual current. Conventional A-type cannot detect it, and in the case of DC residual current superposition, A-type residual current detection may fail, so B-type residual current detection is required.

Based on standards, superior to standards (IEC62752, IEC62955)

For residual current detection of charging piles, there are standard requirements both at home and abroad; overseas (IEC62955, IEC62752) standards are enforced, and as charging piles become more and more mature, domestic standards for residual current are gradually aligned with IEC, and further requirements are made for the protection of smooth DC residual current.

Our product, An integrated RCD protection module that detects both 6mA DC and 30 mA AC. Surely, an B type internal RCM has to be installed on the EV charger internal PCBA, but this is way cheaper than the B type RCCB, Unit price usually around 15-30$.